Suited to Your Requirements.

Exactly.

We know you need a plastic injection company for your upcoming manufacturing of a new product.

Bringing your brilliant idea to life is on us. Contact us for mold design, or deliver us your existing mold, we are responsible for making your products suited to your requirements, exactly.

How It Works?

Enquiry

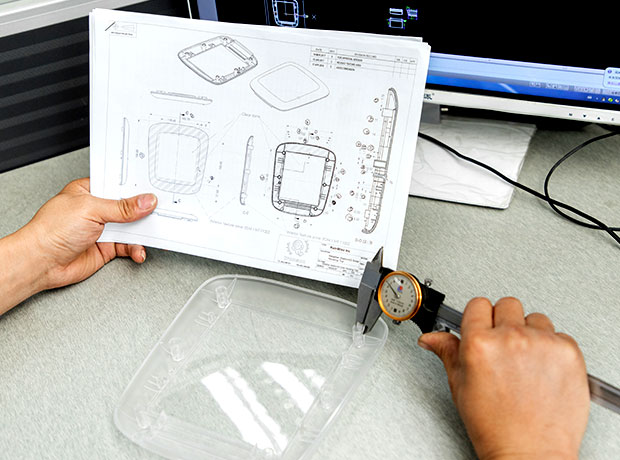

Provide us with your concept or 2D/3D drawing of your product. Tell your detailed requirements on materials, quality, etc.

Quotation

We get back to you with the price, lead time and our review on the design, aiming to reduce possible material waste to a minimum.

Prototyping

Using 3D printing or trial production, we deliver the prototype for final confirmation on the mold design.

Mold Making

Upon agreeing on the mold design, we arrange fast and accurate mold making to keep your production schedule on track.

Mass Production

We promise stable quality within your required lead time. Further processing and transportation are available.

Count on Our Capacity

50+ Injection Machines Running 24/7/365

Our injection machines ranging from 30–1000 tonnes help fulfill heavy loads perfectly.

Regardless of whether you need high-volume plastic parts order or low volume order, we can complete your order within the agreed lead time.

Mastery of Injection Techniques

Perfect plastic parts are made by perfect techniques.

Our technicians with more than 10 years of experience can even detect the slight change of weather. A change of specification shall be made upon humidity and temperature changes to ensure plastic performance.

Advantages of SAMBO Injection Molding

Suitable Materials Save Your Cost

In accordance with your product requirements and budget, our material specialists are able to offer you a perfect composite material solution to achieve the best function and with the smallest cost possible.

We make recommendations from among 100+ materials including basic polypropylene, engineering-grade ABS, and other.

All of the materials we selected meet the RoHS, REACH, and California Prop 65 standards.

Higher Efficiency, Shorter Lead Time

We invest heavily in 50+ injection molding machines ranging from 30 to 1000 tonnes to ensure your high-volume plastic parts are delivered more quickly.

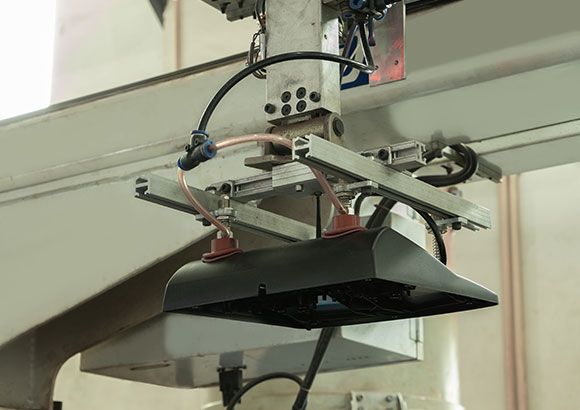

Scientifically designed shift schedule allows us to operate 24/7 for maximum efficiency, while being equipped with the following devices:

-

Manipulators;

-

Automated material handling & feeding.

Quality First

We carry out the quality control in every step that influences the injection molding quality.

The quality of your products generates from our precision plastic mold design and mold making.

Furthermore, our professionals monitor the finished products every 2 hours and adjust the production parameters according to the dynamic and diverse environment.

Industries we Served

Don’t worry even if you don’t find your product listed below. We have capabilities to handle any custom plastic parts you might need.