10+ Years of INJECTION MOLDING EXPERIENCE Helps to Bring Your Perfect Product to Market.

SAMBO is an injection molding manufacturer with expertise in designing molds for manufacturability.

We understand that you have designed your products to perfection, while our experience in producing cost-effective plastic injection solutions makes your products even more perfect.

We employ our industry know-how to simplify the tool design where possible, aiming to ensure that ultimately what we offer is a flexible, tailored solution which will allow us to create real injection molded parts in a rapid lead time.

Our Holistic Capabilities

-

Design

Critical foundation of a smooth and cost-effective production.

-

Prototyping

Ensuring an accurate mold design and pre-production confirmation.

-

Tooling

Advanced machineries in-house to control tools quality and fast delivery.

-

Injection Molding

Realizing custom plastic components molding with our molding technology.

-

Processing

Spray painting, electroplating, assembling and product testing that cover the whole life of a product.

From Concept to Product in as Fast as 5 days.

Step 1: 2D/3D File Uploading

Provide us with your product file and all your requirements on materials, lead time, etc. and get a quick response from us.

Step 2: Manufacturability Review

Our experienced engineers produce analysis reports on production limitations and possible solutions to them based on the review of your design.

Step 3: Quick Quotation

Upon agreements on the modified design, we calculate the cost of all the parts and offer you the final quotation.

Step 4: Rapid Prototyping

Rapid prototyping is available for mold review and adjustment. We will connect your product to the market, quickly.

Step 5: Production

All parts are manufactured in SAMBO's factory. Highly automated machines, expert engineers, and outstanding plant management contribute to high precision plastic parts.

Industries We Served

Don’t worry even if you don’t find your product listed below. We have capabilities to handle any custom plastic parts you might need.

SAMBO Manufacturing

With 50+ state-of-the-art machines in-house, we are able to handle high volume projects within limited time.

The lead time matters, while the plastic performance takes up even a more important share in our manufacturing process.

You get what you designed with our fully engineered manufaturing system.

Tools Making >> Plastic Injection Molding >>SAMBO's Successful Cases

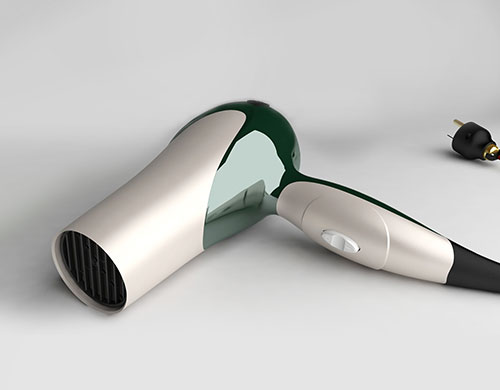

Hair Dryer Project: A Perfect Product Starts From A Perfect Design

We had successful experience in providing injection solution of a hair dryer with a unique design. We received a hair dryer sample which had 2 separated parts with a visible joint in the middle. Our client emphasized that there should not be any seam or open joint between the 2 parts when they are assembled. Through our constant effort, we not only minimize the seam but also made it barely visible.