A Longer Lifespan of Your Molds is Guaranteed.

A well-designed mold is supposed to present excellent capacities including thermal stability, corrosion resistance, toughness and the rest.

We take all of these determinants into consideration. We guarantee that every mold is designed with a scientific structure and every single component is processed within tight tolerance limits.

Mold Base Purchasing

Our reliable mold base suppliers deliver mold bases to us within the prescribed timeframe so that we are able to promptly start the processing and shorten the lead time.

We know it’s hard to keep pace with ever-changing market needs.

Upon receiving the mold base, and before proceeding with further processing, we conduct careful examination of the mold base to prevent possible mistakes right from the very beginning.

Steel Processing

The steel in its rough shape is milled into a more dedicated state with the help of a milling machine.

The milled mold parts meet their accurate specification by the extraordinarily precise CNC machines.

While CNC machines are not suitable for processing some mold parts with special curves, we adopt electrical discharge machining to fulfill the task, dedicatedly and accurately.

We make sure your mold is made with high precision for manufacturability. Wire cutting helps to correctly produce shapes and patterns of a mold.

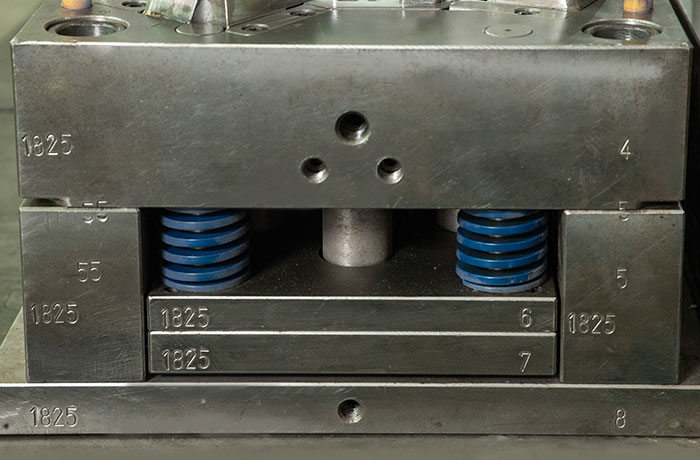

Molds Assembly ---

No Mistake is Allowed.

Not Even One.

With all parts well processed and ready, our technicians start to assemble the mold in strict compliance with the assembly drawing.

A high precision assembly is ensured by the designed order for assembling the upper and lower dies.

We try every means to reduce the time for finishing a full set of molds and to ensure your production schedule is respected.

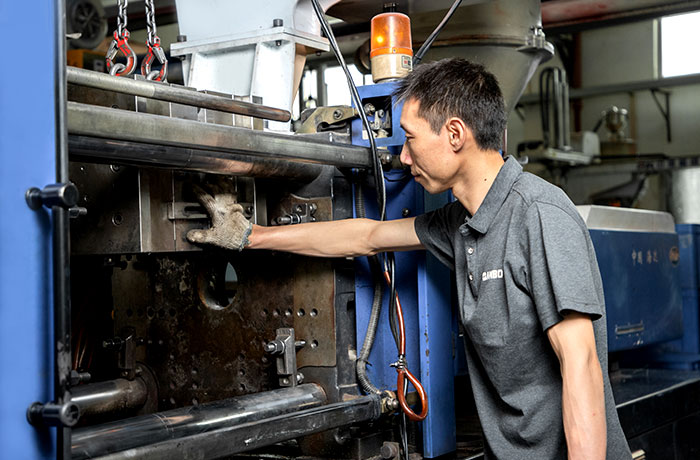

Trial Runs Before

Mass Production

All molds manufactured by SAMBO shall stand the trial runs before being used for mass production of the plastic parts.

We can't afford to be wrong since the price is too high.

Temperature, material, color, internal stress, etc. are taken into consideration in the trial runs so as to ensure a smooth mass production. Only when the mold is totally corrected will it be sent to you or our injection workshops.

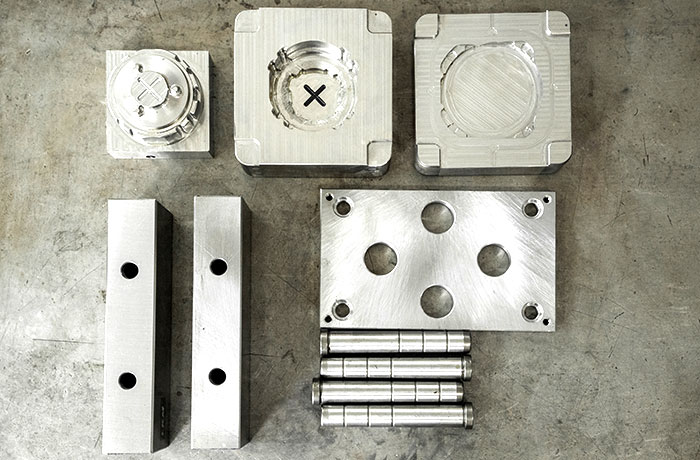

All Components with S.N.

Designed For Tracable

Quality Management

SAMBO's molds are designed and manufactured to exceed demanding customer expectations for quality, reliability, and performance.

Whenever there are quality problems, we offer a quick solution since we have marked S.N. of all components of our molds including mold bases, pins, ejectors, lifters, bushings, guides and alignment devices, etc.

Tell us the S.N. of the malfunctioning part and we will figure out the problem and solve it as soon as possible.