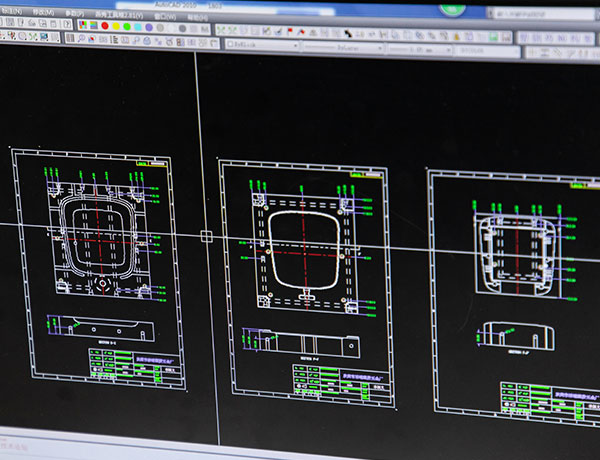

- AutoCAD

- Unigraphics

- Solidworks

- Pro/E

Computer Aided Design

The perfect mold should be structurally designed for manufacture, and tooling and component parts should be considered as well.

We specialize in engineering design of plastic products/parts and plastic molds, with the 3D and 2D models created with modern CAD software.

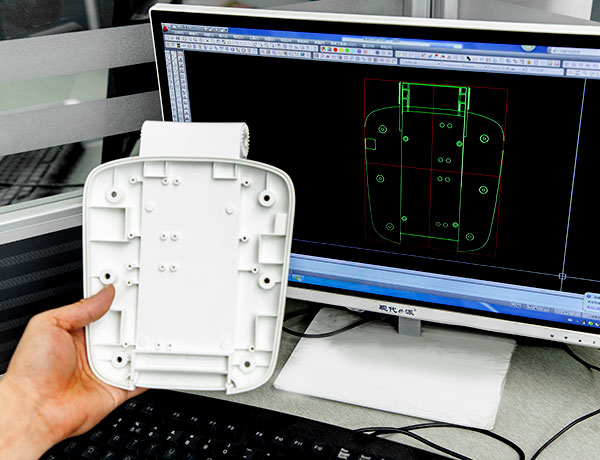

Get the Initial Solution

from Our Engineers

Our expert engineers will discuss and work out an initial solution

in-house and will then offer an optimization advice according to your product structure or drawings.

Get a full mold design guide to a cost-effective mold, including gates & runners design, sliders optimizing, surface finishes, etc.

Prototype-based

Remodifications

Upon receiving the prototype, our engineers convene to discuss necessary modifications on the mold.

Your involvement in the process also contributes to our final mold that should work flawlessly. We do not start a trial run before both parties agree to it.

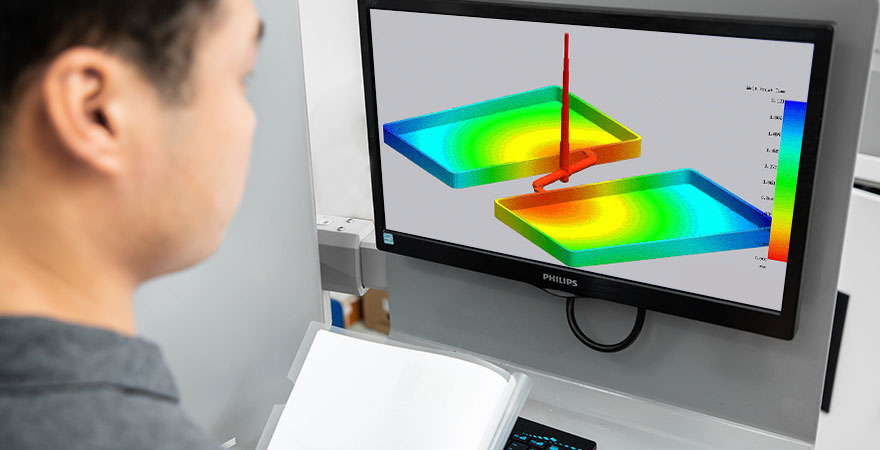

Focusing on Precision, Lifespan and Cost

Mold Flow Analysis: With your product files, we analyze the mold flow simulation to ensure the design for manufacturability and precision, based on the product structure, cavity design, wall thickness, etc.

The mold flow simulation and analysis will eliminate most of the defects that may occur during manufacturing. Potential problems will be found and solved early on.

The mold life expectancy depending on the annual sales of plastic products, affects the way we design the mold.

Our engineers are proficient in mold design with respect to the mold functions and adjusting the linkage systems of the molding machine to extend the mold lifespan.

Depending on your volume and our technical analysis, we optimize the mold design concerning your budget.

During technical designing, we use our knowledge about mold design to optimize the cavity and the pins layout, aiming to avoid the shot size being wasted and reduce costs.